Plastic Laminate can be the Right Answer in the Right Place

Slate gray plastic laminate ready for cutting.At ARHTX, we do a lot of plastic laminate (p-lam) construction. P-lam is a great material for offices, restaurants, hospitals, schools, anywhere where there are high traffic and high use areas. P-lam can take the challenges of abuse and neglect and come out unscathed. But p-lam has gone beyond just being a utilitarian product and is now being used in the right places in homes. To create p-lam that looks finished and elegant in any setting, the trick, as always is in the details.

P-lam is created by processing sawmill byproducts like sawdust and wood shavings into particle board that is then fused with resins under tremendously high heat, creating a versatile product that comes in a huge spectrum of colors. Because of the array of shades to pick from, p-lam is finding its way into residential applications including garage storage, laundry room cabinets, and playroom shelving.

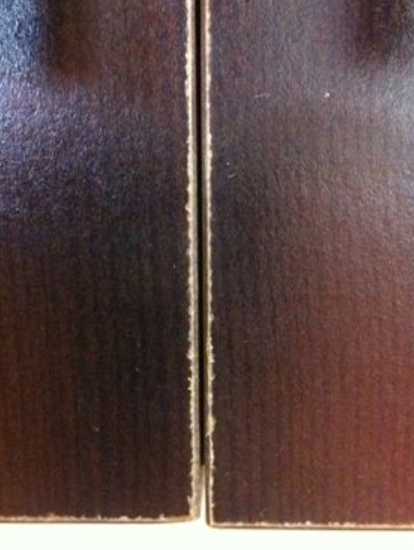

When we work with p-lam, we make sure every edge is sanded completely which includes open face areas, but also those edges that need to fit together tightly and minimize the seaming. The edgebanding that’s applied to the open surfaces needs to be flush with all adjacent surfaces.

A recent finished p-lam project with ADA accessibility and sink inset in matching laminate counter.You also need the right equipment to work with p-lam. Chip out, that rough, chewed looking surface or edge results when the wrong saw or blade is used for cutting the material. The specialized tools and techniques needed for p-lam make it difficult to work with for the DIYer.

P-lam should never look like this on the edges.When making the decision to use laminate versus plywood construction, first consider the area of the home or office where it will be used. Setting hot items or pounding on the laminate surface will destroy the product. Laminate cabinets also don’t add much value to the resale of a home. Keeping laminate in utility areas like laundry rooms that are separate from the rest of the living area or in storage areas, optimizes the capabilities of p-lam and lengthens how long it is attractive and useful.